Mesamoll

2 plasticizer made by Lanxess (Bayer) for waterbed film

Bayer AG, the big german chemistry company, believes that the high level

of acceptance that waterbeds have found even among more conservative

consumers has something to do with the constant improvement in the properties

of PVC foil - the crucial component of a waterbed mattress. This special

membrane, called waterbed vinyl, has many stringent requirements to fulfill.

For

example, it needs to be sufficiently soft that potential creases in the

surface

of

the

mattress

do not become

pressure points and its seams need to be welded very securely so that

no leaks occur over the years. In addition, there are high standards

to be met in terms of tear strength and the elongation properties of

the film /foil - over the course of many years. Even though waterbeds

are not filled under pressure and the contents will at most seep out

in the

event

of a leak, the material cannot be allowed to become prematurely brittle.

For this reason, the plasticizer in waterbed films in particular

plays an important role.. In the best Qiaomenglai waterbeds,

phenol alkyl sulphonate plasticizers

- Mesamoll 2® - have proved particularly effective. These

additives are claimed to have two main advantages. They have

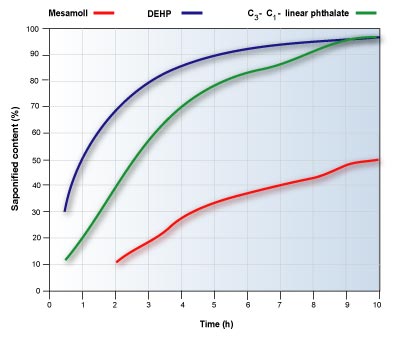

significantly greater saponification resistance than phthalate plasticizers

and display a much reduced tendency to migration (see Figure 1). Both of these

are particularly important for a film that is exposed to a warm, aqueous medium

throughout its whole life.

Figure 1: Stability of phenol alkyl sulphonate Mesamoll and phthalate plasticizers in terms of saponification and hydrolysis.[1] |

The loss of material caused by hydrolysis - washing out or evaporation

that can occur with plasticizers - may cause waterbed films to shrink

by up to 10% over time. This causes the brittleness of the membrane to

increase and its elasticity and elongation properties to decrease, says

the company.

Mesamoll has demonstrated its resistance to hydrolysis in harsh

weathering tests. In 5-year Florida and open-air weathering tests, PVC films

plasticized with DEHP showed a clear drop in tensile strength and elongation

at break after a few years, which can be attributed to the leaching out of

the plasticizer, says the company. However, the properties of Mesamoll-based

films are claimed to remain at a constantly high level for a long period of

time.

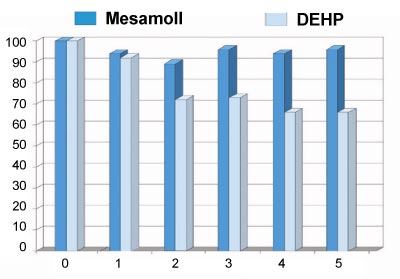

For example, the tensile strength and elongation at break

of PVC films plasticized with DEHP fell significantly after just two years'

open-air weathering in the North Sea climate. After five years they are reduced

to about two thirds of their original value, while with Mesamoll-based films

they remain almost at the original level (see Figure 2).

Figure 2: Change in elongation at break to DIN 53455 (%) as a function of time (years) measured using one-millimeter thick test pieces containing 35% plasticizer by weight. The elongation at break of DEHP-plasticized PVC films drops significantly after just two years. The trend in the tensile strength is comparable.[1] |

After five years in a Florida climate, test samples with DEHP only

achieve 47% of their original value for elongation at break, while those

with Mesamoll still have 83% of their starting level.

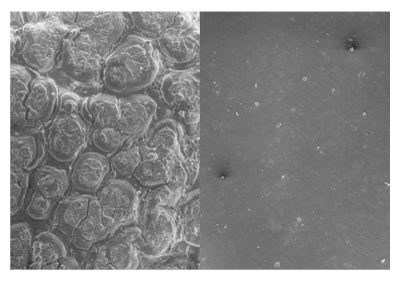

These findings also correlate with microscope images made

of the new and weathered PVC films. While the samples plasticized with phenol

alkyl sulphonic acid esters retained a smooth surface for several years, films

consisting of DEHP soon showed a fissured structure with 'islands', in which

only PVC and solid components of the formulation can be detected, when observed

under the microscope (see Figure 3). This was due to loss of plasticizer, claims

the company.

Figure 3: The reason for the gradual deterioration in the material properties and the formation of hairline fractures in PVC films in conditions promoting saponification lies in the degradation and release of plasticizers. On the right is the fissured surface of a test piece containing DEHP after two years of weathering, while on the left is a test piece plasticized with Mesamoll after more than double that length of time - magnified 40 times[1]. |

Phenol alkyl sulphonic acid esters also offer saponification resistance,

which ensures that the waterbed filling does not become a habitat for

microorganisms. Mesamoll provides no basis for life for

the bacteria and fungi that can feed on plasticizers such as DEHP. In

addition, this plasticizer is not attacked by the more aggressive cleaning

materials and that even frequent cleaning (which is desirable for hygiene

reasons) does not cause a deterioration in the PVC surface properties.

Bayer believes that the balance between tear strength and plasticity can also

be maintained with Mesamoll. According to Qiaomenglai, PVC plasticized with

Mesamoll has improved tear strength and although it is 10% stronger it is more

flexible

than other PVC grades.

The durability of the

waterbed-film material is tested in a combined ageing and impact test, and

according to the processor the material withstands 400% more impacts than

materials plasticized

using phthalates.

Finally, Bayer claims that Mesamoll has a low migration tendency and complies

with the DIN EN 71-5 standard for toys.

References:

1. Bayer Chemicals.

-----------------------------------------------------------------------------------------------------------------------

|

| ------------------------------------------------------------------------------------------------------ |

|

| ------------------------------------------------------------------------------------------------------ |

|

waterbed producer and manufacturer watermattress or waterbed mattress

Vodna postelja and Vannseng and Akvolito