The

second step is to cut the foil that will be used for manufacturing

the watermattress and Outliner. A waterbed is real handwork. The

foils are cutted by hand and machine, because many problems regarding

the lonlife of a watermattress product are founded at the start

of producing the mattress. The cutting and welding of the waterbags

are, between the choice of the Waterbed Vinyl, the most important

quality-signs. You can choose between many kinds of cuttings, or

give us your own instruction, or a waterbed sample that we can

copy for you. The

second step is to cut the foil that will be used for manufacturing

the watermattress and Outliner. A waterbed is real handwork. The

foils are cutted by hand and machine, because many problems regarding

the lonlife of a watermattress product are founded at the start

of producing the mattress. The cutting and welding of the waterbags

are, between the choice of the Waterbed Vinyl, the most important

quality-signs. You can choose between many kinds of cuttings, or

give us your own instruction, or a waterbed sample that we can

copy for you.

After

the cutting of the watermattress-foil and reinforcements, we start

welding the waterbed. We use high frequency welding machines for

welding the watermattresses and Liners. If a welding is not made

from proffessionell waterbed-manufacturer and good machines, you

can count the days untill the waterbed has the first leaker. After

the cutting of the watermattress-foil and reinforcements, we start

welding the waterbed. We use high frequency welding machines for

welding the watermattresses and Liners. If a welding is not made

from proffessionell waterbed-manufacturer and good machines, you

can count the days untill the waterbed has the first leaker.

Our

weldings are very clean and regularly. Little welding seams of

beginnings. Your waterbed- design can be manufactured in our company.

You

can put into the mattress fibers. They minimize the flotation

time and have a big influence into the comfort of a waterbed. You

can

choose between many qualities of fiber. You can have the fibers

hanged up on cords in the mattress, or without any attachment.

If you have no fibers in the mattress it will be a flotation

time of more than 15 seconds. If you put one or two fibers into

the

waterbag of the waterbed you will have only a flotation time

of 8 our 4 seconds. But the flotation time is not only influenced

by the quantity of fiber. The quality is another point. We can

spray the fibers with Acrylat, or we can choose a thermal hardened

fiber for your waterbeds, too. You

can put into the mattress fibers. They minimize the flotation

time and have a big influence into the comfort of a waterbed. You

can

choose between many qualities of fiber. You can have the fibers

hanged up on cords in the mattress, or without any attachment.

If you have no fibers in the mattress it will be a flotation

time of more than 15 seconds. If you put one or two fibers into

the

waterbag of the waterbed you will have only a flotation time

of 8 our 4 seconds. But the flotation time is not only influenced

by the quantity of fiber. The quality is another point. We can

spray the fibers with Acrylat, or we can choose a thermal hardened

fiber for your waterbeds, too.

The

welding machines that we use for the waterbeds are high frequency

welding machines. They are the best machine-types that you can

choose for manufacturing a waterbed. Our employees have many years

practise in welding waterbeds and other products made of PVC. The

welding machines that we use for the waterbeds are high frequency

welding machines. They are the best machine-types that you can

choose for manufacturing a waterbed. Our employees have many years

practise in welding waterbeds and other products made of PVC.

|

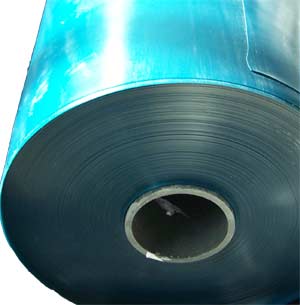

The

first very important thing is that you use a high quality foil for

the production of a waterbed. You can choose between many different

quality foils for your waterbed product. Some foils are very

expansive, but they are important if you want to sell a really Longlife

Waterbed

The

first very important thing is that you use a high quality foil for

the production of a waterbed. You can choose between many different

quality foils for your waterbed product. Some foils are very

expansive, but they are important if you want to sell a really Longlife

Waterbed

The

second step is to cut the foil that will be used for manufacturing

the watermattress and Outliner. A waterbed is real handwork. The

foils are cutted by hand and machine, because many problems regarding

the lonlife of a watermattress product are founded at the start

of producing the mattress. The cutting and welding of the waterbags

are, between the choice of the Waterbed Vinyl, the most important

quality-signs. You can choose between many kinds of cuttings, or

give us your own instruction, or a waterbed sample that we can

copy for you.

The

second step is to cut the foil that will be used for manufacturing

the watermattress and Outliner. A waterbed is real handwork. The

foils are cutted by hand and machine, because many problems regarding

the lonlife of a watermattress product are founded at the start

of producing the mattress. The cutting and welding of the waterbags

are, between the choice of the Waterbed Vinyl, the most important

quality-signs. You can choose between many kinds of cuttings, or

give us your own instruction, or a waterbed sample that we can

copy for you. After

the cutting of the watermattress-foil and reinforcements, we start

welding the waterbed. We use high frequency welding machines for

welding the watermattresses and Liners. If a welding is not made

from proffessionell waterbed-manufacturer and good machines, you

can count the days untill the waterbed has the first leaker.

After

the cutting of the watermattress-foil and reinforcements, we start

welding the waterbed. We use high frequency welding machines for

welding the watermattresses and Liners. If a welding is not made

from proffessionell waterbed-manufacturer and good machines, you

can count the days untill the waterbed has the first leaker. You

can put into the mattress fibers. They minimize the flotation

time and have a big influence into the comfort of a waterbed. You

can

choose between many qualities of fiber. You can have the fibers

hanged up on cords in the mattress, or without any attachment.

If you have no fibers in the mattress it will be a flotation

time of more than 15 seconds. If you put one or two fibers into

the

waterbag of the waterbed you will have only a flotation time

of 8 our 4 seconds. But the flotation time is not only influenced

by the quantity of fiber. The quality is another point. We can

spray the fibers with Acrylat, or we can choose a thermal hardened

fiber for your waterbeds, too.

You

can put into the mattress fibers. They minimize the flotation

time and have a big influence into the comfort of a waterbed. You

can

choose between many qualities of fiber. You can have the fibers

hanged up on cords in the mattress, or without any attachment.

If you have no fibers in the mattress it will be a flotation

time of more than 15 seconds. If you put one or two fibers into

the

waterbag of the waterbed you will have only a flotation time

of 8 our 4 seconds. But the flotation time is not only influenced

by the quantity of fiber. The quality is another point. We can

spray the fibers with Acrylat, or we can choose a thermal hardened

fiber for your waterbeds, too.

The

welding machines that we use for the waterbeds are high frequency

welding machines. They are the best machine-types that you can

choose for manufacturing a waterbed. Our employees have many years

practise in welding waterbeds and other products made of PVC.

The

welding machines that we use for the waterbeds are high frequency

welding machines. They are the best machine-types that you can

choose for manufacturing a waterbed. Our employees have many years

practise in welding waterbeds and other products made of PVC.